Recently, affected by industry factors such as tight virgin paper supply chains and raw material shortages, the price of core raw materials for paper packaging products has fluctuated, directly leading to increased costs of mainstream packaging products such as corrugated cartons, color cartons, and color boxes. This has brought cost pressure to enterprises relying on bulk packaging purchases, and the operating profits of some enterprises have also been affected as a result. As an enterprise focusing on high-quality paper packaging production, we are well aware of the importance of stabilizing product quality and providing sustainable solutions at this time—all our packaging products are made of high-quality virgin paper materials. While adhering to the bottom line of quality, we help customers alleviate cost pressure and overcome the industry's raw material shortage cycle through process optimization, customized services, and recycling advocacy.

From the perspective of product material and process control, we always take virgin paper materials as the core, ensuring that every product meets quality standards and has recyclable environmental attributes, reducing the hidden costs of "inferior packaging rework" and "repeated purchases" for customers from the source. In the production of core products corrugated cartons, we use high-strength virgin corrugated paperboard. Whether it is the e-commerce corrugated carton used in e-commerce logistics or the wholesale corrugated cartons meeting bulk procurement needs, they all meet the quality requirements of durable corrugated cartons for shipping—the fiber strength of virgin paper materials is higher, and the made cartons are anti-extrusion and wear-resistant, which can effectively reduce the product damage rate during transportation and avoid additional losses caused by packaging problems. For customers with printing needs, we use water-based ink technology to produce printed corrugated cartons and custom color cartons. The ink has strong adhesion and clear, long-lasting patterns, and will not affect the subsequent recycling of cartons due to material issues; for products such as laminated color boxes that need to improve protection, we use environmentally friendly laminating materials, which enhance water resistance and scratch resistance while ensuring that the laminating layer can be separated from the paper, without hindering the recycling of cartons, taking into account both practicality and leaving room for sustainable utilization.

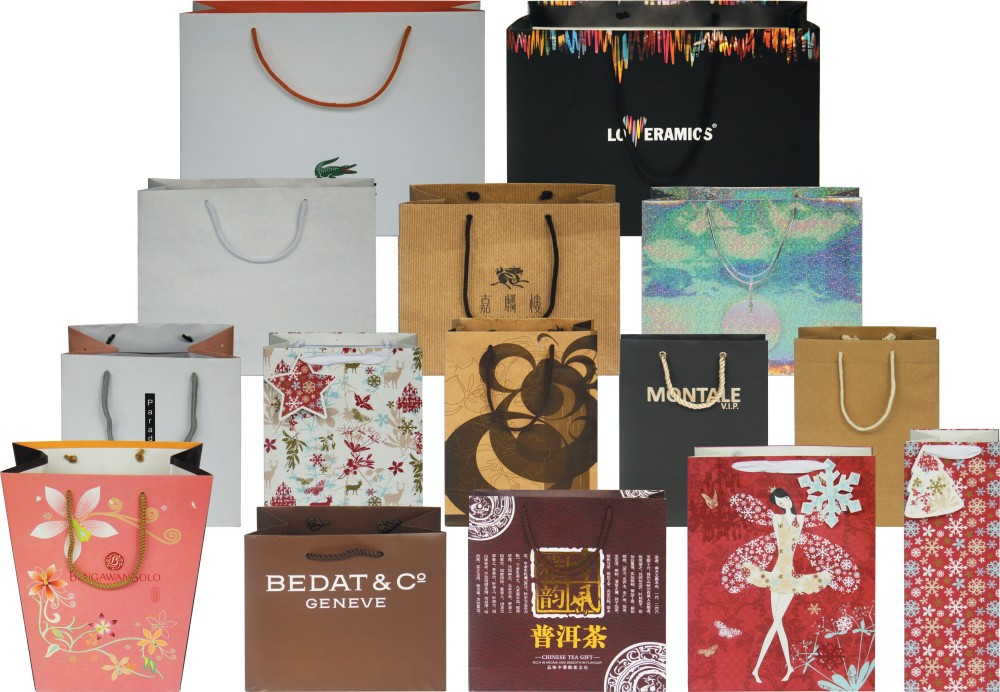

In terms of customized services, we help customers reduce packaging waste and indirectly alleviate the cost pressure caused by price increases through "on-demand design and precise matching" solutions. For example, for courier paper boxes frequently used by e-commerce customers, we provide custom corrugated carton services—designing carton specifications precisely according to the size and weight of the customer's products, avoiding packaging material waste caused by "small items in large boxes", and optimizing the carton structure to reduce the amount of virgin paper materials used while ensuring protection, controlling procurement costs for customers from the perspective of "reducing consumption". For customers in the food industry, the food-grade paper food boxes and disposable paper cups for beverages we produce are all made of virgin paper materials that meet food contact safety standards, without using recycled raw materials, ensuring the safety of packaging in contact with food, so that customers do not have to worry about "packaging compliance rework"; for retail paper display stands and shopping mall paper tote bags in retail scenarios, we improve the reuse rate of products through modular design—for example, foldable paper display stands can be used repeatedly in multiple promotional activities, and paper tote bags made of thickened virgin kraft paper can be used multiple times, reducing the frequency of customers' repeated purchases and indirectly spreading the cost of a single purchase.

Quality assurance is the core confidence to cope with cost fluctuations—we know that when the price of raw materials rises, reducing quality to cut costs will only make customers face greater risks of "product loss caused by packaging damage". Therefore, even when the cost of virgin paper rises, we still strictly control the entire production process: virgin paper materials must undergo multi-dimensional testing such as fiber strength, air permeability, and hygiene safety before being put into storage; when producing custom gift boxes and luxury gift paper bags, every process from die-cutting, folding to gluing is equipped with quality inspection links to ensure that the finished products are free of wrinkles and unglued, meeting the exquisite needs of gift packaging; when producing wholesale corrugated cartons in bulk, we improve accuracy through automated production lines, reduce waste of leftover materials, and improve the utilization rate of virgin paper materials while ensuring quality. This adherence to "no quality compromise" allows customers to avoid paying extra for "low-cost and low-quality packaging", which actually reduces comprehensive operating costs in the long run.

Promoting the recycling of paper packaging products is an important way to alleviate the pressure of virgin paper shortage and reduce customers' long-term costs. The recycled paper materials can re-enter the industrial cycle after treatment, reducing the demand for new virgin paper materials and indirectly alleviating the price pressure caused by virgin paper shortage. For example, the recycled printed corrugated cartons can be converted into raw materials for producing paper trays and color paper bags after treatment, which not only reduces resource waste but also eases the burden on the industry's raw material supply chain, forming a benign closed loop of "use-recycle-cycle".

Facing the current industry environment of virgin paper shortage and carton price fluctuations, we will not simply pass on cost pressure to customers. Instead, we will work with customers to cope with challenges through a three-dimensional solution of "optimizing processes to reduce waste, customizing services to reduce waste, and advocating recycling to promote circulation". In the future, we will continue to deepen the process innovation of virgin paper packaging, at the same time, we will expand the coverage of eco-friendly paper packaging, making "high quality" and "sustainability" the core reasons for customers to choose us, helping more enterprises stabilize their operations amid cost fluctuations and realizing the healthy and sustainable development of the paper packaging industry.